Important:

Use these instructions along with the tool, parts page or manual.

Notice: To avoid damage to the motor housing, use the Special Repair Tools designed for the disassembly and assembly of this motor. Disconnect the tool from the air supply. Use the appropriate wrenches to hold the work spindle stationary and remove the accessory.

Disassembly

Right-Angle Head:

Step 1

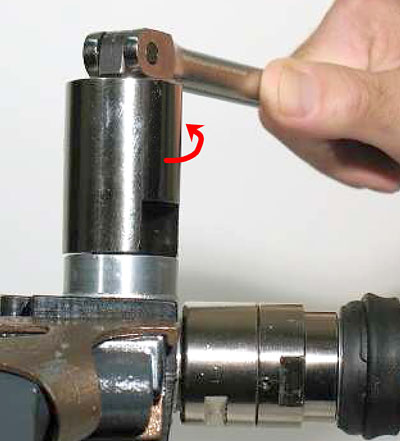

Use the 96461 Repair Collar to hold the 02031 or 02052 Housing in a vise, with the work spindle pointing up. Use the 50971 Lock Ring Tool to remove the 02035 Lock Nut.

Turn counterclockwise.

Step 2

Pull the right angle work spindle, bearing and bevel gear out

of the housing.

Step 3

Remove the lubricant wicks and any shims.

Step 4

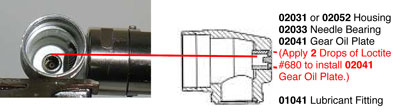

The 02033 Needle Bearing rarely requires replacement.

Only remove the 02033 Bearing, and the 02041 Gear Oil Plate when the bearing needs to be replaced.

Step 5

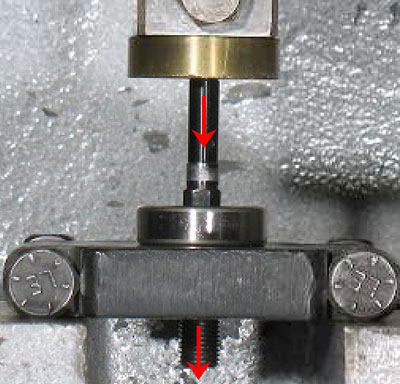

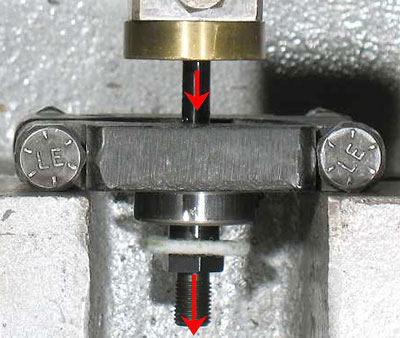

Fasten the 96346 Bearing Separator (2") between the bevel gear and the 54520 Bearing. Place the bearing separator with the work spindle, bearing and bevel gear in the 96232 Arbor Press (#2) with the working-end pointing down.

Step 6

Use the bearing separator and the arbor press to remove the 54520 Bearing.