Important:

Use these instructions along with the tool, parts page or manual.

Notice: Shut off the air supply and depress throttle lever to dissipate the remaining air. Carefully disconnect the tool from the air supply hose. Remove the abrasive belt and contact arm assembly. Use the Special Repair Tools designed for the disassembly and assembly of this motor.

Assemby of Dynafile® III

Step 1

Install the 01010 Spacer onto the rotor. Install .003" (~0.80 mm) shim thickness into the 01008 Front Bearing Plate. Install the 01007 Bearing into the front bearing plate. Install the bearing and plate onto the rotor.

Step 2

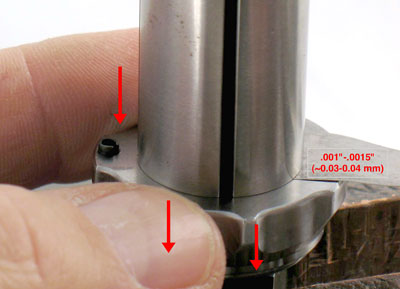

By hand, install the 01708 Rotor Nut. Pull the front bearing plate forward to take movement out of the bearing. Check the clearance between the rotor and plate. Use a .001" (~0.03 mm) thick

feeler gauge.

Notice: The clearance should be .001"-.0015"

(~0.03-0.04 mm). If the rotor/plate clearance needs adjustment, repeat steps 1 and 2. Remove or

add shims as required.

Step 3

Use a 19 mm crowfoot, and a torque wrench to tighten the 01708 Rotor Nut. (T to 17 N•m/~150 in. lbs.)

Step 4

Apply the 95842 Dynabrade Air Lube, 10W/NR or equivalent to the 01185 Vanes and install them into the rotor.

Step 5

Use the Raised Outside Diameter of the 96240 Bearing Press Tool and the arbor press to install the 02649 Bearing.

Notice: Press the bearing all the way into the plate.

Step 6

Install the cylinder and rear bearing plate so that the air inlet openings line-up with each other.

Step 7

Use the Raised Inside Diameter of the 96240 Bearing Press Tool and the arbor press to install the bearing and plate.

Important: Press the bearing and plate down until the rear bearing plate just touches the 01028 Cylinder. This will produce a close fit between the bearing plates

and the cylinder.

Step 8

Install the motor assembly.

Step 9

Carefully fasten the 01739 Housing in the vise with aluminum or bronze jaws so that the rotor spindle is pointing up. Install the 15322 Felt Silencer around the 15314 Air Control Ring and install these into the 15315 Exhaust Cover. Apply Loctite #7649 Primer or equivalent to the thread of the 15315 Exhaust Cover. Apply a small amount of Loctite #567 or equivalent the exhaust cover. Use the 50971 Lock Ring Tool and a torque wrench to install the exhaust cover.

(

T to 34 N·m/~300 in. lbs.)

Notice: Over tightening vise will damage housing.

Step 10

Insert a 3/16" hex key through the drive wheel and into the end of the 55025 Rotor to hold it stationary. Use groove pliers to tighten the drive wheel.

Important: Use a tachometer to check motor speed and

to verify proper operation.

Step 11

Install the air motor into the housing. Use a 9/64" hex key to fasten the motor with the 95311 Screw and 40029 Cam Lock.

Notice: For belt housing, contact arm and valve assemblies, refer to the exploded view and the additional instructions contained in the tool parts page or manual.

Click here and enter your model number for the current parts page or manual.