Disassembly:

Step 1

Position the 51989 Repair Collar around the motor housing. Fasten the tool in a vise so that the work spindle is pointing up. Use a HEAT GUN to warm the planetary gear casing or planetary cover to soften the thread adhesive.

Use an adjustable wrench to remove the planetary gear casing or planetary cover. Turn counterclockwise.

Important: Use Disassembly Instructions - 1 hp Straight

for repairing the air motor assembly.

Step 2

Use a 2.5 mm or 3/32" hex key to remove the set-screw.

Step 3

Remove the planetary reduction.

Step 4

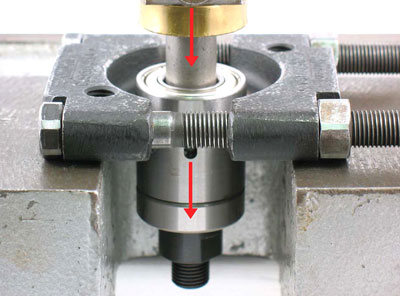

Fasten the 96346 Bearing Separator (2") with the FLAT SIDE facing the RING

GEAR and the BEVELED SIDE facing the

02552 Bearing.

Important: Place the bearing separator and the planetary reduction in the 96232 Arbor Press (#2) with the spindle pointing down.

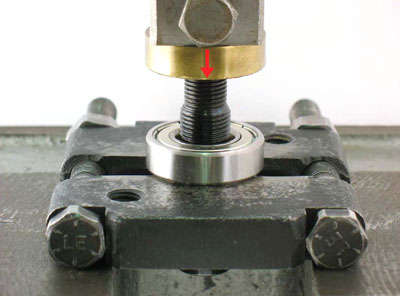

Step 5

Use a 5/8" or 16 mm diameter press tool to push the planetary carrier out of the 02552 Bearing. Remove the ring gear, shafts, and planet gears.

Step 6

Fasten the planetary carrier in a vise with aluminum or bronze jaws so that the spindle nut ispointing up.Use an adjustable wrench to remove the spindle nut.

Important:

Turn counterclockwise.

Step 7

Use the arbor press to push the planetary carrier out of the

02552 Bearing.

Planetary Gear Disassembly Complete.

Clean and inspect parts before assembling.